How to repair washing machines with their own hands: how to troubleshoot and fix them

Knowing the device of an automatic washing machine to deal with the typical breakdowns of appliances from Electrolux or Siemens on their own is not difficult.

Knowing the device of an automatic washing machine to deal with the typical breakdowns of appliances from Electrolux or Siemens on their own is not difficult.

The most important thing in this task is a properly performed diagnosis, through which you can establish what caused the malfunction.

By the way, even complicated repairs of Vestel or Candy appliances can be done by yourself.

Parts for washing machines are relatively inexpensive, and the tools you will need only a couple of screwdrivers and ring wrenches.

Contents

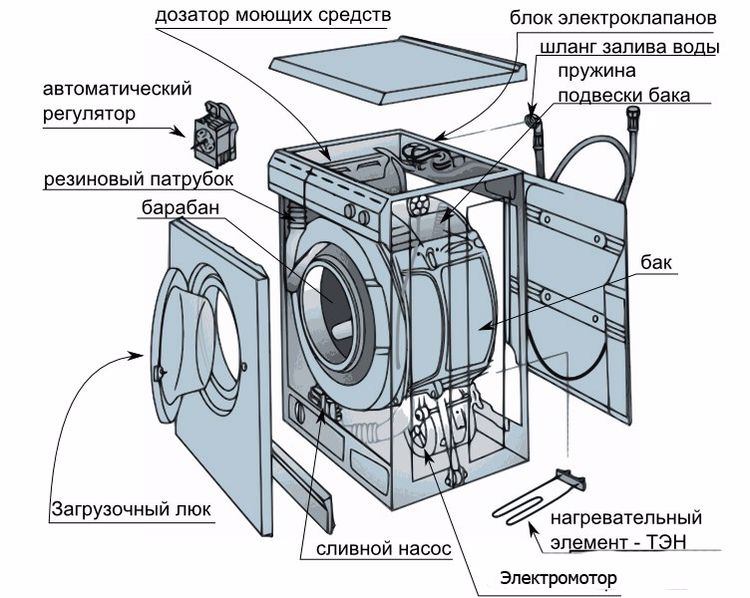

Construction of a Washing Machine

The basic principle of operation of a washing machine, whether LG or Zanussi, is as follows:

- There is a drum inside. It rotates by means of an electric motor, which is connected to it by a belt. The drum is enclosed in a sealed ABS-plastic case, in the base of which the bearing is pressed.

- The rotation speed of the electric motor (as well as its direction) is controlled by a digital unit. This is a kind of mini-computer, in which all modes of operation of the washing machine are programmed.

- The set of water is carried out through a special electric valve. There is no pump for this. Therefore, the washing machine works properly only if the water supply is maintained at a constant pressure. With a weak set of water intake is not possible.

- Drainage of water is carried out with the help of a pump.

- The drum is held on special shock absorbers. Excessive vibration at high revolutions of the electric motor is damped by them.

- Water after intake is heated by a heating element - TEN.

- Also, the washing machine has a set of sensors. With their help, the temperature of water, the level of intake, the tightness of the hatch (door) is controlled.

Accordingly, technically, the washing process is performed as follows:

- the user loads the laundry into the drum, selects the washing program via the control panel (it is directly connected to the digital unit);

- the washing machine checks if the door is closed, then the water intake begins;

- the electric motor is switched on, the drum rotates according to the program set by the control unit;

- after washing, rinsing and spinning is completed, the pump is started to pump out the dirty water to the sewer.

Independent replacement of parts

Most often, users of popular brands of appliances have to face a failure:

- TEN. Responsible for heating water. Located behind the back wall of the washing machine at the bottom ("inserted" into the drum). Estimated service life is 5 years.

- Drive belt. Also located behind the back wall, connects the electric motor and drum.

- Hoses. Located outside, but to remove them will have to partially disassemble the washing machine.

Change of the heating element

To replace the THEN, you need:

- Remove the back of the washing machine.

- Unscrew the 3 screws fixing the heating element. One of them holds the temperature sensor - it must be carefully removed, cleaned from traces of scale (if any). Also disconnect the wires connected to the THEN terminals.

- Pull out the heating element.. To do this you can use pliers. You will have to use force, since in most cases the heating element will be heavily encrusted.

- Install a compatible new heating element. Also put in place the temperature sensor, connect the wires.

- Check the operation of the heating element. Enough to turn on the washing in hot water. How to understand that the heating works properly? Simply touch the hatch with the palm of your hand. Another option is to measure the current consumption of the washing machine. When the heating element is on it will be over 1,5 - 2 kW (without heating, the washer, as a rule, consumes less than 500 - 700 watts).

Replacing the drive belt

It is considered necessary to change the belt if it deflects by more than 3 centimeters when pressure is applied to it. This means that it is very stretched, so it may slip during operation.

To replace the drive belt, proceed as follows:

- Remove the back of the washing machine.

- Remove the belt from the pulley of the drum. If you can not do this, you will need to unscrew the electric motor and move it to the side to loosen the tension.

- Remove the belt from the motor pulley.

- Install the new belt in reverse order.

- Put the electric motor back in its place.

After - check that it works. It is recommended to start the washing machine and turn on the spin at maximum speed. If the belt slips, you will hear a characteristic "whistle".

Replacing Hoses

To replace the water intake hose, the washing machine will not need to be disassembled.

The step-by-step is performed as follows:

- Shut off the water supply line. Disconnect the hose from the shut-off valve.

- Unscrew the water intake hose from the inlet coupling.

- Check the sealing rubber. If necessary, clean the strainer (only allow coarse debris to enter the drum).

- Install new hose.

But to replace the drain hose, you will need to remove the back wall of the washing machine, as it is attached directly to the siphoning pump. The procedure is as follows:

- Remove the back wall of the washing machine.

- Locate the sump pump. In most cases it is located at the bottom left, can be covered with a shielding insert.

- Unscrew the clamp of the drain hose, disconnect it from the pump connection.

- Install a new hose, tighten the clamp.

It is obligatory to check after 1 - 2 washing cycles whether water oozes in the place of attachment of the drain hose.

Eliminating noise from the washing machine

External noise during automatic washing machine operation occurs in the following cases:

- Wear of the drum drive bearing. One of the most difficult breakdowns, as it will be necessary to completely disassemble the washing machine.

- Wear of the electric motor rotor.

- A foreign object got inside the drum. Most often these are buttons, metal elements of clasps.

Bearing replacement

Replacing the drum drive bearing should be done only if you have experience in carrying out such repairs.

The process step by step on the example of a Samsung machine is as follows:

- Remove the back and top walls of the washing machine.

- Remove the motor, drive belt, and heating element.

- Disconnect the shock absorbers. The drum must be held, so the procedure should be carried out by two people. Or under the sealed plastic casing put some kind of a cleaner.

- Remove the sealing collar (at the front, behind the door). Most often this will also require removing the hatch.

- Pull out the drum in the plastic hermetic case.

- Remove the plastic casing. And this is where the difficulties may arise, since most washing machines have it sealed from the factory. That is, it has to be cut with a grinder. In other models, it is enough to unscrew the parts of the box, and then - disconnect them (in the place of the seam are treated with sealant, so you will have to apply force).

- At the base of the plastic housing is pressed bearing - it is this bearing that needs to be replaced. Knock out most often you have to use a hammer.

- Install the new bearing. Install the drum. As a rule, there are marks where this is done (or protruding grooves, so the bearing cannot be installed incorrectly).

- Assemble the plastic drum box. Be sure to also apply a water-resistant sealant along the seam that is resistant to high temperatures. Most use automotive (for cylinder block gaskets).

- Install the drum in place, assemble the washing machine in reverse order.

Motor Rotor Wear

Electric motor yourself can also be repaired, but only if the problem is with the brushes. In such cases, as a rule, the spinning does not work properly (the rotation speed is too low).

Therefore, the recommended repair option is to replace the motor, which is performed as follows:

- Remove the back of the washing machine.

- Disconnect the power cable from the electric motor, as well as the control connector (sometimes they are connected through a single port).

- Unscrew the motor. It is attached in most cases to special metal brackets with screws.

- Remove the drive belt.

- Put the new motor in place, put the belt on its pulley.

- Connect power cable and control connector.

- Check the operation (start the wash or spin).

Foreign objects in the drum

Get the foreign objects will be possible only if they are metal. To do this, you can use an ordinary magnet.

If you can not remove the object in this way, for example, if the washing machine Ariston or ARDO was converted to a baker, it will be necessary to completely disassemble the drum.

Replacement of electronic modules

If the control unit is faulty, the only option for its repair is a complete replacement.

It is performed according to the following algorithm:

- Remove the back and top wall. Behind them, as a rule, there is a plastic insert (fastened with plastic latches).

- The control unit is located at the front (just behind the button block).

- Unscrew the retaining screws.

- It is also recommended to take a picture of how all connectors are connected.

- In some models you must also disconnect the control panel buttons beforehand.

- Remove the digital unit. Install the new one in reverse order.

Replacing the hatch and detergent tray

Replacement of the hatch, as a rule, is carried out, if its glass was broken or the fastening of the hinges is damaged.

The replacement process is as follows:

- Open the door.

- Hinges are fastened on the left side. It is enough to unscrew 3 - 4 screws.

- Remove the door.

- Install the new door.

- Check the tightness of the assembly.

Chute replacement

How exactly the tray is removed should be clarified in the technical manual, since the process may differ in different models of washing machines Veko, Atlant, Whirlpool and other brands. In most cases, to do this, just open the compartment, press the special plastic clip and pull the tray toward you.

Also note that new trays may have shipping films at the connections to the nozzle of the electric valve (through which the water to flush the detergent). They must be removed beforehand.

Safety rules when repairing household appliances

When carrying out any repair of the washing machine, you should adhere to the following rules:

- Be sure to preliminarily de-energize the appliances. That is, disconnect it from the mains. Further it is recommended to wait 1 - 2 hours and only after that to start repair. It is necessary for self-discharge available inside capacitors (as a rule, there are near an electric motor, and also on a control board).

- Be sure to use grounding when making repairs. The best option is to use an anti-static wrist strap. This is especially important when repairing the control unit. Even a small amount of static electricity can cause it to malfunction.

- It is imperative that the washing machine only be connected via a circuit breaker (RCD) after repairs have been carried out. This will protect it from damage in the event of a short circuit (for example, if the electric motor has been installed incorrectly or the control connector is faulty).

Malfunction Prevention

To increase the life of the washing machine, it is recommended to adhere to the following tips:

- After completing each wash, open its door ajar. This will not allow moisture to accumulate inside. After all, it is because of her most often fails the control unit, since oxides are formed on the board.

- Regularly wash the detergent tray. The manufacturers recommend to do it in general after each wash. Otherwise, the abrasive components from the washing powder will accumulate there, as well as limescale. And all this, sooner or later, will get into the drum. Also, such particles often "stick" to the heating element, which causes its overheating and subsequent failure.

- Make sure that there are never kinks in the hoses. It is recommended to replace the gaskets every 12 months.

- Clean the strainer on a regular basis. This is especially important to do for those connected to the city water supply. After all, during maintenance often performs flushing of water pipes. And the remains of debris, together with rust can get inside the washing machine.

- Adjust the washing machine so that it is level on the floor. A construction level should be used. This also prevents unnecessary vibration.

- If the washing machine vibrates strongly when washing or spinning - use a special anti-vibration mat or attachments to the feet. These are sold in almost all plumbing stores. The main thing is to have a stable platform. If the house has wooden floors, you will have to perform a local pouring of concrete.

- Choose the right mode of washing. You should not always use the maximum heating of water. From this, firstly, a much higher consumption of electricity, and secondly - significantly reduces the operating life of the heating element.

To sum up, to repair the washing machine with your own hands and replace the failed components is quite possible. If any difficulties arise, then you can always contact an authorized service center of the manufacturer.

You should also remember that if you disassemble the washing machine yourself, the terms of warranty service are canceled. That is, after that the repair will have to perform only at your own expense.

Useful video

From the video you will learn how to repair the washing machine and what to pay attention to: